Multiply 0.1974 times 32 and the answer comes 6.32. You need to find the nearest drill bit size in 32nds of an inch. Now apply for the numbers in the formula with 84 percent. In our case, Dbm = 0.252 inch and Ni = 20 percentage should be between 70 to 85. Here, Dh means the drilled hole size in inches Dbm means the basic major diameter of the thread Ni is the number of threads per inch.

#PRINTABLE METRIC TAP DRILL CHART FULL#

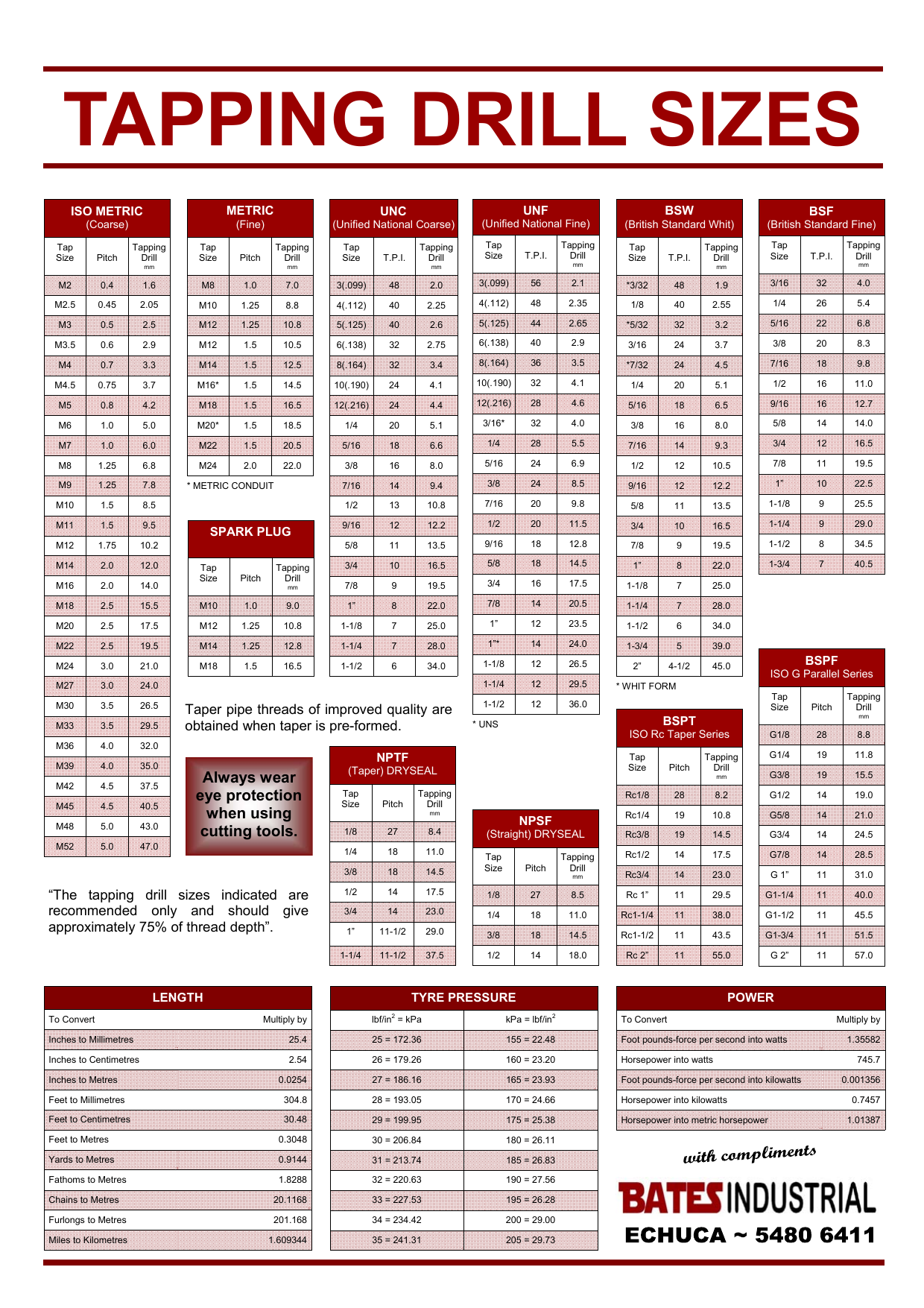

The next step is to use the formula Dh = Dbm - 0.0130 (percentage of the full thread desired/ Ni) to find the correct drill bit size. If you want a drill bit for a ¼ – 20 tap, where ¼ is the diameter and 20 stands for the thread pitch, then the overall measurement of the tap’s diameter is 0.252 inches. We’ll describe the way of calculating the drill size with a few steps below:įirst, you need to measure the overall diameter of the tap. If the thread is M5x0.75 then the tapping drill is 5-0.75 = 4.25mm

Both are calculated the same way by subtracting the pitch from the diameter of the thread. There are threads of two sizes metric and imperial. Tap Drill Bit Chart Tap Drill Size Formula Well, with the help of a basic formula you can find the correct drill bit for the thread tap. So, how’d you found out what sized drill to use? So, you need the proper sized drill to pre-drill the hole first. If the hole is not of the appropriate size, it won’t fit the tap. You need a specific-sized hole for the tap. Every tap is tapered for the first few threads that help it to start the cutting process easier.Įach tap is marked with three distinct numbers: When you tap a hole, it creates female threads within the hole. There are grooves or valleys cut into the tap’s body. It has several flutes in its design and a higher number of flutes increase its strength. People use taps to cut threads for bolts or screws into materials such as plastic, metal, or even wood.Ī tap can remove material from a punched hole or a pre-drilled hole. The best thing about this tap is that it can cut threads all the way to the bottom of the hole. These taps are best used after the taper or plug tap has been used to cut the initial thread. It has only 1 or 1 tapered cutting edge before you engage the full cutting force. It is also a bit more aggressive than taper tap and typically has between 3 to 5 tapered threads at the tip.īottoming tap – this is the most aggressive top of them all. Plug tap – its cutting edges have a less pronounced taper and give it a bit less gradual cutting action than taper tap. This provides a less aggressive cutting action. There are almost 8 to 10 threads tapered from the tip. Taper tap – you can identify a taper tape by visible and pronounced tapering at the cutting edges. Let’s discuss a little about all of them. The three tap types are taper, plug, and bottoming tap. The threads just behind the cutting edge may be relieved or backed off to produce sharpness. The interruption between the threads and flutes creates the cutting edge. There may be two, three, or four flutes between the to cut screw threads in a hole or a nut.

The performance of the bit is analyzed with the geometry and sharpening of the cutting edges.

The threaded percentage needs to be considered you want when you’re done tapping to know about the right drill bit size for your particular tapping application. When it comes to tapping drills, one size doesn’t fit all. The size recommended in most drill bit size charts is very often not the best size to use. Get the best hardware fasteners from Newport Fasteners store at a great price! Having a good metric tap drill chart is a very handy thing while buying or deciding on the right kind of fasteners for the work.

0 kommentar(er)

0 kommentar(er)